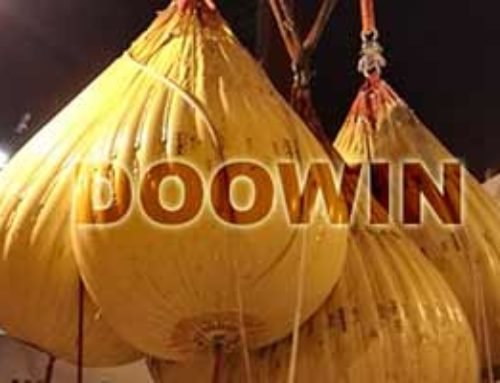

Water filled water weight bags are simple and safe crane test weights designed to provide proof load testing instead of traditional solid load test weights.

DOOWIN load test water weight bags are designed for proof load testing the lifting equipment and structures that request proof load weight testing. When it’s newly finished, or periodic check or maintenance. Such as crane load testing, beam load test, lifeboat davit load test, derrick load testing, overhead crane load test. So, this water-filled water weight bags offer one kind of innovative crane load test weights solution. Most noteworthy, it has the advantages of Safety, Economy, Convenience, High Efficiency.

Proof load test water weight bag is one system including water filled weight bags and all its accessories. Moreover, these water weight bags are designed that the lifting set is separate from the water bag body. As a result, the failure of any one webbing element will not result in failure of the lifting set nor cause a local overload of the weight test water bags.

So how to do 50ton load testing with water bag? There are 3 ways to follow:

- Preparation before load testing

First, check the hook of the crane. If it is single-hook, you will need load cell, shackles, water weights bag, filling and discharge hose, water supply, pulley and rope. If it is double-hook, you will also need a sling.Second, clear the site. You need to ensure that no sharp items in the field. Any sharp items may harm the body of the water bag.

Third, prepare the spot big enough. With DOOWIN 50ton proof load bag, the height of your site will be no less than 9.2m ( the empty height of load test bag), the width will be no less than 4.6m( the filled diameter of water weights bag). Of course, different clients have different load testing requirement. For example, vacillate the crane hand to left and to the right, swing up and down, the request for load testing space is different.

In addition, if your site with less height but more width, you could consider the low room water bag. It could customize according to your request.

- Operation of load testing water bags

If your crane is single-hook, connect the shackle, load cell and the water bag. Set up the filling and discharge hose in its right position. Install a pulley and rope on top of the water bag, the rope is long enough to control far away.

If your crane is double-hook, settle the sling between hook and shackle. This will help the hook to bear equal weights. Then do the same operation as above.

Open up the load cell. The crane will lift empty water bag slowly. During this period, please take care to avoid the friction between the bottom of the water bag and ground. When the bottom totally away from the ground and in a good position, you could start fill water to the bag.

Close the valve on the discharge hose. Control the discharge hose far away from the ground with rope on a pulley. Tie the rope on hand of water bags.

Connect the filling hose to the water supply. You could know the total weights with assistance of the load cell.

When the weights reach required one, stop filling water into weights bag. Crane operates according to different request.

- After load testing operation

Put down the discharge hose, open the ball valve to let water out. After the water completely out, pull down the discharge hose of weights bag. Control the weight bag body with S shape folded into the plywood box. Pull down the filling hose, load cell and shackles.

It is easy to operate, right?