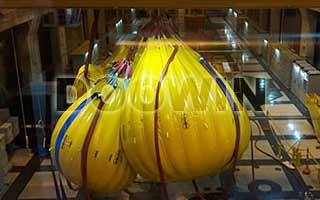

The use of water bags is a safe, effective technique for load testing overhead, jib and gantry cranes in different environments. DOOWIN offers expert load testing services for overhead cranes and crane bridges. We use our load-indicating equipment and proof load water bags for the service.Whether you use the cranes in production facilities, mills or port facilities, we could provide accurate, cost-effective proof-load test results. It ensures that the crane can operate safely within expected parameters.

DOOWIN can develop a custom overhead crane load test. It could ensure that the test results are accurate and meet the test objectives. With load testing water bags, we could slowly apply the test load. So it allows for technical issues to be identified and corrected before reaching the full test load. In addition, we could drain the water weight bags when the hoisting system or brakes are compromised during testing. There is no need to lower the test weight, So, when we conduct the tests in areas with low headroom or tight spacing, proof load water bag could work better. Because in this area, you could not use solid weights. While the water bags still could work while empty, providing testing of the complete crane structure.

The overhead crane load testing includes initial commissioning of the crane and overhead bridge, after repairs, or periodic inspections.

Whether your overhead crane is located offshore, in a shipyard, near a port, at a mill or production plant, DOOWIN water weight bags will be your first choice.